Sandwich construction is a technique from the aviation and high-performance industry that's now being applied in modern vehicle building.

Structure

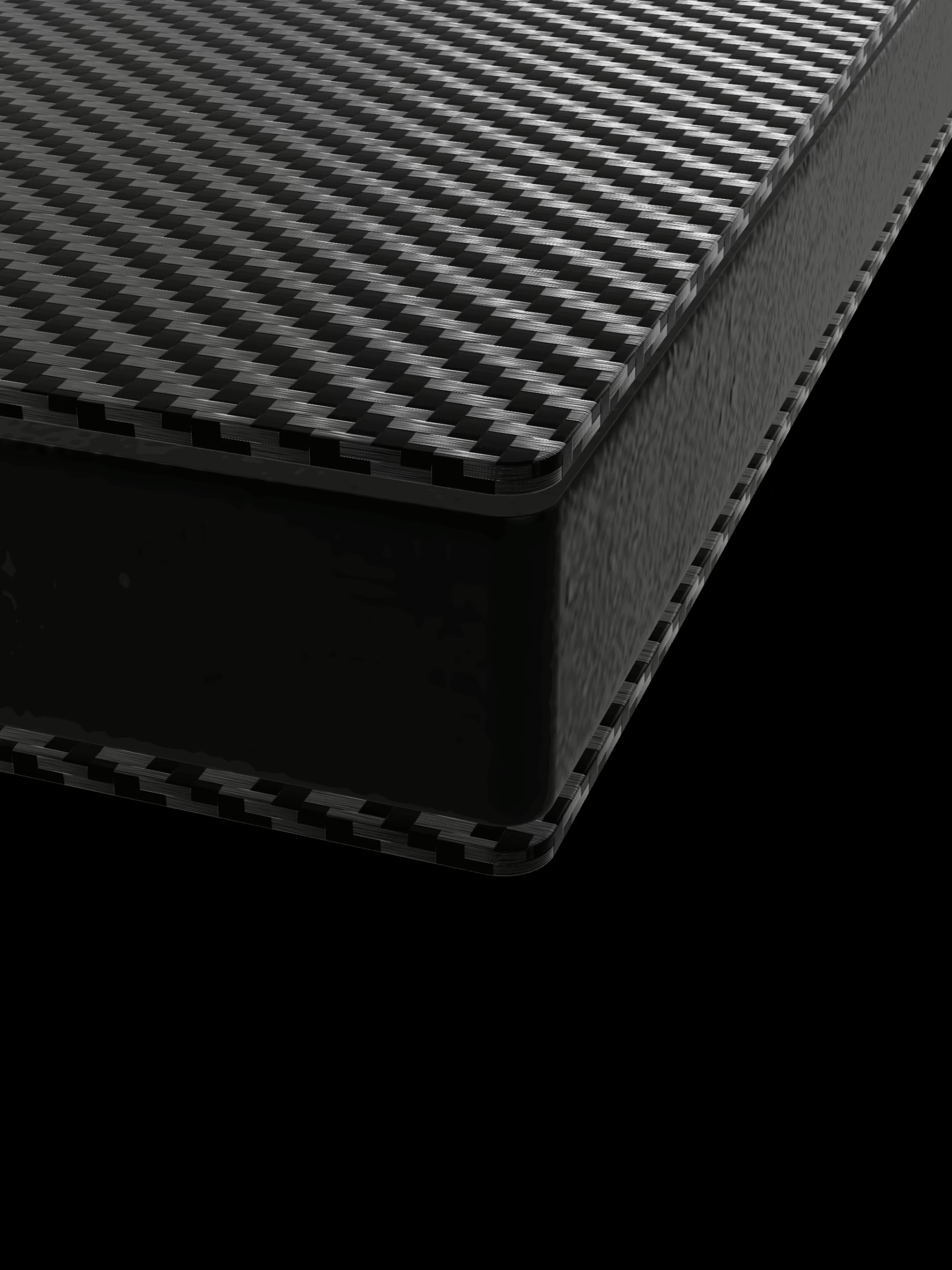

The structure consists of three layers:

- Outer carbon fiber layers

- A lightweight core (foam or honeycomb core)

- An inner carbon layer

How It Works

This structure works on the principle of the I-beam. The spatial separation of the outer layers creates enormous bending stiffness at minimal weight.

The core acts as a "spacer" and gives the component volume without significant weight increase.

Advantages for Campervans

In the 3.5-ton segment, carbon sandwich construction offers crucial advantages:

Weight Savings

Enables more payload for technology, batteries, and water tanks – crucial for true autonomy.

Stability

Significantly higher than aluminum, ideal for off-road use and temperature fluctuations.

Longevity

Corrosion-free and UV-resistant. The material practically doesn't age.

Thermal Properties

The core provides insulation and reduces heat loss – less heating energy needed.

Applications at VANYX

VANYX uses this technology for:

- Carbon rear extensions

- High roofs

- Specialized construction components

The goal: Combine luxury, off-road capability, and autonomy in a lightweight vehicle.

Conclusion

Carbon sandwich isn't a gimmick, but a technically sound solution for the challenges of modern campervan building.